NEWS

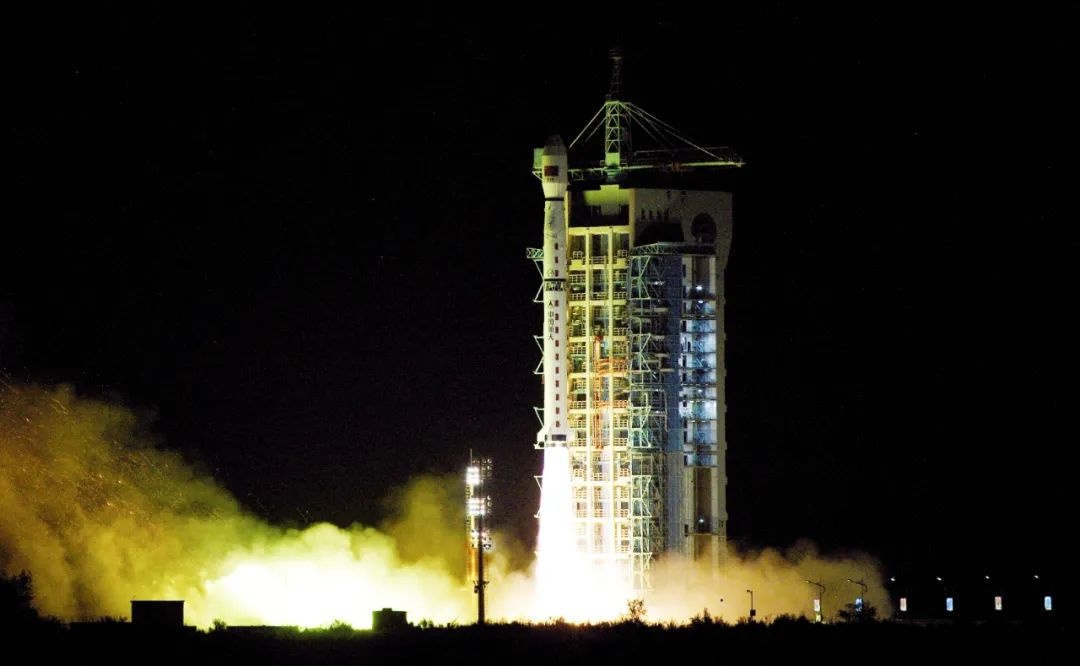

Long March 4C with Yaogan-33 03 launched successfully

发布时间:

2023-12-08 10:27

At 2:14 AM on September 7, 2023, the Long March 4C launch vehicle blasted off from the Jiuquan Satellite Launch Center, successfully inserting the Yaogan-33 03 satellite into its reset orbit. The launch mission achieved a complete success. Both the satellite and the launch vehicle were developed by Shanghai Academy of Spaceflight Technology (SAST).

The launch vehicle test team implemented a strengthened digital quality assurance system to ensure the successful completion of the mission.

The Long March 4C launch vehicle is a three-stage launch vehicle with liquid propellant at normal temperature. With excellent performance and wide applications, it has the capability to adapt to various types of satellites and different orbit requirements, allowing for launching multiple types of satellites with flexible launch plans and implementing single- or multiple-satellite launches. Its carrying capacity in the sun-synchronous circular orbit can reach 3 tons (at an orbit height of 700 kilometers)

Due to the complex and changing weather conditions at the Jiuquan Satellite Launch Center caused by seasonal transitions, the test team conducted comprehensive technical briefings with the launch site upon their arrival. In order to minimize the impact of weather factors, the team adhered to the culture of "pragmatism plus" and worked simultaneously on multiple tasks, striving continuously with high quality and efficiency in the recovery and transportation of launch vehicles. They set a new record for the shortest working time in the technical area. Additionally, the test team held daily meetings to review tasks, meticulously examine weak links and ensure quality through digital quality assurance measures. These efforts resulted in controllable conditions and contributed to the successful outcome of the launch process.

This mission is the 102nd launch of the Long March 4 launch vehicles and the 194th launch of the Long March launch vehicles developed by SAST. It is also the 486th launch of the Long March launch vehicles.

Satellite test team optimized processes to improve efficiency and ensure timely and high-quality completion of research development and launch missions.

The satellite development team upholds the principles of "independent innovation, hard work, cautious attitude, strong cooperation, and harmonious win-win", and adopts the work style of "ensuring milestones, overcoming difficulties, sharing responsibilities, and achieving results". Through innovative thinking, process optimization, and comprehensive confirmation measures, they ensure the timely and high-quality completion of development and launch tasks.

The chief commander and chief designer, together with the project office, various research and development units, have demonstrated a strong commitment to innovation, meticulous planning, strict control, and collaborative efforts. They have successfully completed all satellite development work according to the plan and finished on schedule. The satellite development team considered factors such as product coordination, research and development personnel, and testing equipment. They created and managed a comprehensive plan flowchart to guide the preparation and execution of main and auxiliary work plans. They coordinated the acceptance of satellite products and ensured that the satellite platform and payload products were loaded once for continuous tests after assembled in stages, significantly saving the time occupied by testing equipment and personnel.

The team actively carried out the SAST's requirements for optimizing the satellite development process, and fully summarized the successful experience, resulting in a series of refined procedures. These include the seamless integration of individual components in a single assembly, meticulous transportation and leak inspections of the fully assembled satellite, rigorous three-stage electrical testing, and the safe transport of powered batteries. Notably, they have eliminated unnecessary pyrotechnic deployment tests at the launch site and dispensed with tower attitude control closed-loop tests. During operations at the launch site, they carefully consider factors such as personnel, equipment, tools, and site conditions. This comprehensive evaluation allows for the proper arrangement of the satellite workflow, ensuring efficient completion of tasks at the launch site. Their meticulous planning of the mission schedule enables orderly arrangements that contribute to the accuracy and excellence in every operation.

The team continuously strengthened quality control during the test process at the launch site. Following the quality management requirements of CASC and SAST for tests at the launch site, they set the quality objective clear as "100% qualified unpacking rate, passing all tests on the first attempt, no quality issues during the process, and successful completion of the launch test mission". Adhering to the principles of "systematic planning, strict implementation, meticulous confirmation, and continuous optimization", the team closely integrated the technical process of the satellite launch site with the requirements of quality confirmation. They developed 18 quality confirmation projects, carefully planned the timeline, and assigned responsibilities to specific individuals. Consequently, they had produced 40 quality confirmation forms and 309 process inspection records, covering "every step, component, and position" at the satellite launch site. Paying special attention to one critical process, two key product categories, four critical operations, and two important tests, they performed re-comparisons of test data, reconfirmed the product status, and reviewed the final results, effectively ensuring the implementation of risk control measures at the launch site and the successful completion of the launch test mission. Quality personnel continually summarized their experiences, further optimized the quality confirmation system at the launch site, and organized timely confirmations by responsible individuals to ensure that the product quality is assured and the work is steady and reliable.